enCAPsure sound enclosure

enCAPsure sound enclosure

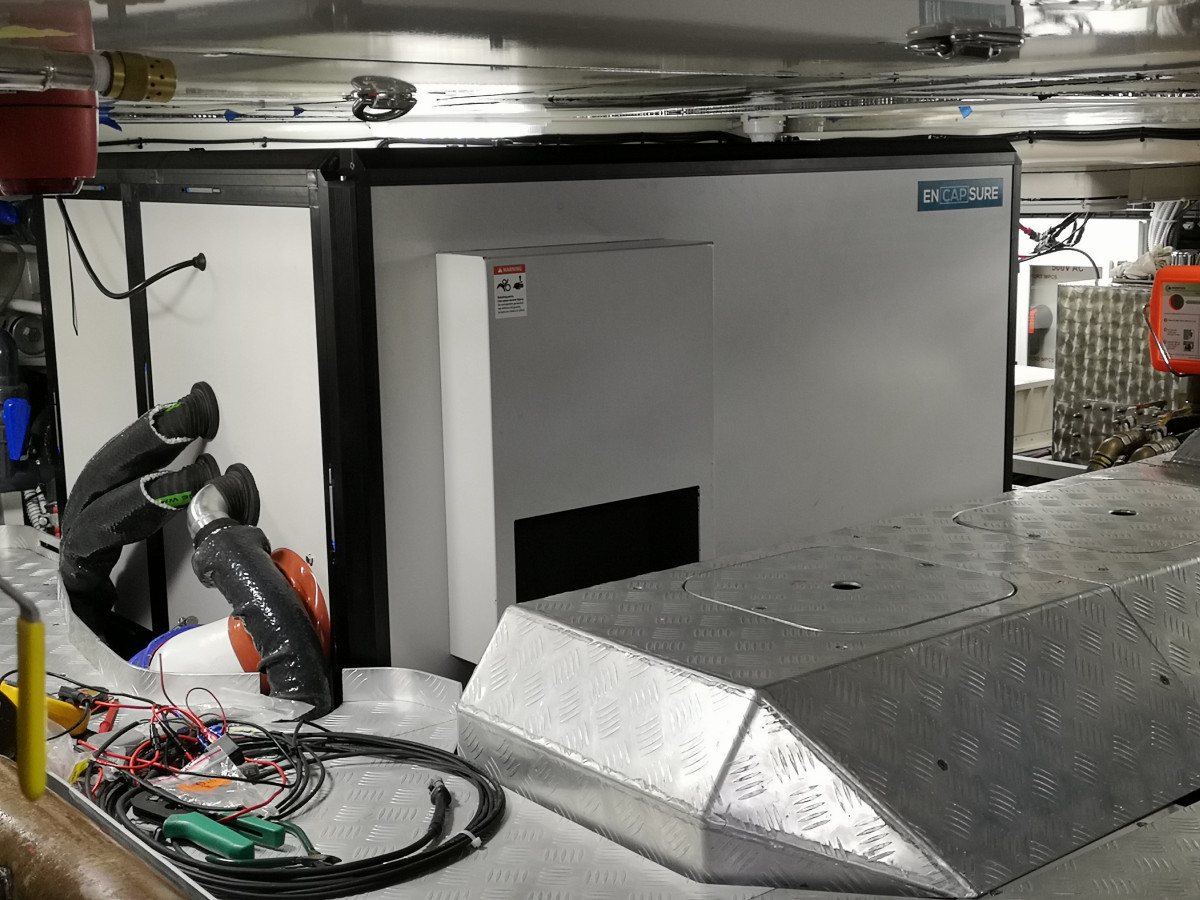

Custom design

As no machine or project is the same, we strive to go beyond the air-borne noise reduction of standard sound enclosures and incorporate any specific requirements from our customer. Being weight or size reduction, an ultra-silent enclosure by using the latest technologes or fully non-combustible constructions.

Our engineering does not stop at the enclosure as we know that an inadequate mount selection, rigid connenctions of appendices and dynamically weak supporting foundations can largely destroy the effect of any enclosure, no matter how good.

When required we can use our 3D noise level prediction software to predict air-borne levels and FEA to analyse the generator foundaton on stiffness and natural frequencies.

Sound insulation materials

The enCAPsure is fitted with purposely selected sound absorption materials, offering excellent sound absorption characteristics and increased overall noise reduction whilst meeting the test criteria of some of the highest fire resistance testing standards.

Not limited to this selection, other sound insulation materials can be offered ranging from ultra-light to non-combustible, all chosen with acoustics, safety and durability in mind.

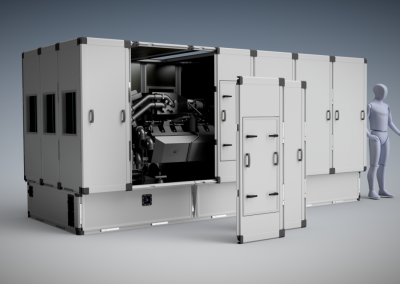

EnCAPsure type 22

EnCAPsure type 45

EnCAPsure type 22

We strive to go beyond the air-borne noise reduction of standard sound enclosures and can incorporate any specific requirement.

Details

Airborne noise reduction

- we strive for a maximum reduction, as no project is the same the reduction therefore will be different per project.

Closure system

- unique patented closure system ensuring a tight fit

Panel thickness

- 22mm standard, aluminium with sound insulation

Sound absorption materials

- excellent sound absorption characteristics

- increase overall noise reduction

- selections ranging from ultra-light to non-combustible

Machinery access

- Custom, all sides possible; there is no framework.

Unique closure system

One key feature of the enCAPsure is the unique patented closure system which ensures tight fit closure along the perimeter of the panels.

Performance

The type 22 enCAPsure panels are tested in our in-house test laboratory in order to fine tune the air-borne noise reduction. When the type 22 panels do not meet the requirements we can design panels with specific acoustic requirements and conduct test procedures at low cost.

Acoustic scanning hardware enables us to detect leaks, panel resonances and performance dips to focus on.

The overall performance of our enclosure depends on a lot of variables such as weight, size, panel types, ventilation, hatches, cable penetrations etc. It is therefore impossible to give an exact air-borne noise reduction value without at least some of the variables known. Indicative values can be given after an initial informative discussion.

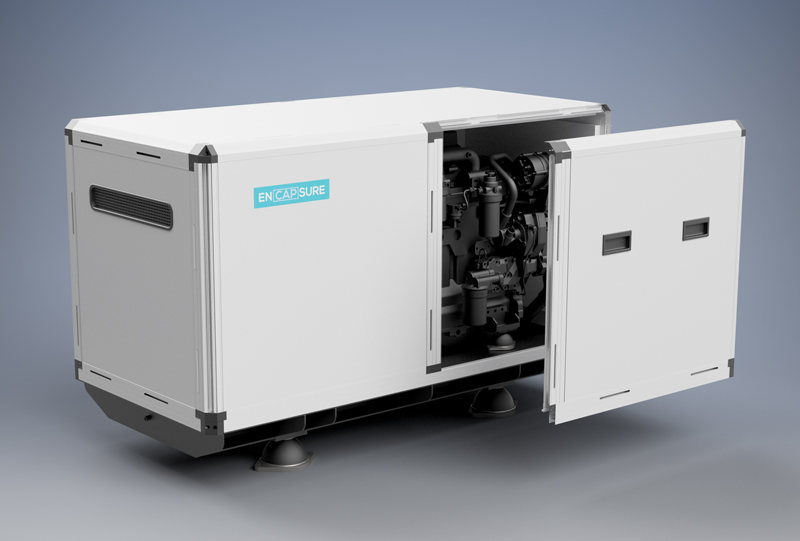

EnCAPsure type 45

We strive to go beyond the air-borne noise reduction of standard sound enclosures and can incorporate any specific requirement.

Details

Airborne noise reduction

- we strive for a maximum reduction, as no project is the same the reduction therefore will be different

Closure system

- unique patented closure system ensuring a tight fit

Panel thickness

- 45mm standard, mixed aluminium/steel panels with integrated sound absorption

Sound absorption materials

- excellent sound absorption characteristics

- increase overall noise reduction

- selections ranging from ultra-light to non-combustible

Machinery access

- Custom, all sides possible; there is no framework.

Unique closure system

One key feature of the enCAPsure is the unique patented closure system which ensures tight fit closure along the perimeter of the panels.

Performance

The type 45 enCAPsure panels are tested in our in-house test laboratory in order to fine tune the air-borne noise reduction. When these standard panels do not meet the requirements we can design panels with specific acoustic requirements and conduct test procedures at low cost.

Acoustic scanning hardware enables us to detect leaks, panel resonances and performance dips to focus on.

The overall performance of our enclosure depends on a lot of variables such as weight, size, panel types, ventilation, hatches, cable penetrations etc. It is therefore impossible to give an exact air-borne noise reduction value without at least some of the variables known. Indicative values can be given after an initial informative discussion.